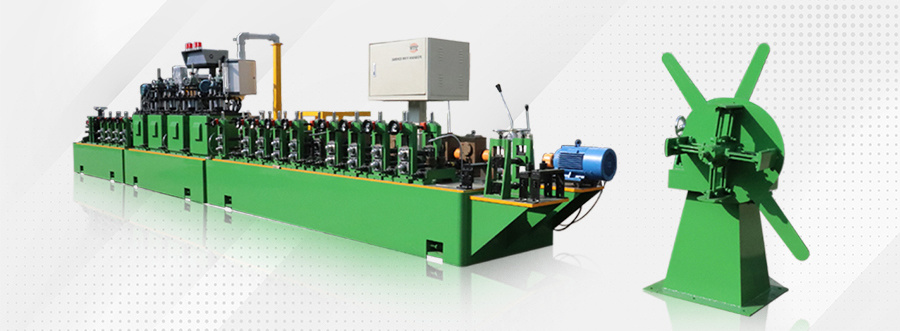

Decorative Steel Pipe/Tube Making Machine

Decorative Steel Pipe/Tube Making Machine can produce steel pipe/tube with ss materials, such as 316,304,409,3201,202. our pipe/tube making machine is W forming , in the welding section we will weld the pipe.

Category:

Phone/Whatsapp:

+86 18818745372

- Description

-

- Commodity name: Decorative Steel Pipe/Tube Making Machine

- Commodity ID: 1070427047483559936

Decorative Steel Pipe/Tube Making Machine can produce steel pipe/tube with ss materials, such as 316,304,409,3201,202. our pipe/tube making machine is W forming , in the welding section we will weld the pipe.

Stainless Steel Tube/Pipe Making Machine is design for produce welded tubes/pipes, which the finished

stainless steel tubes/pipes used for decoration such as furniture,tables, chair legs,storage rack,

public facilities and guardrails, indoor handrails, flagpole,bus racks,etc.

Pipe Making Machine's Parameter Table

Type

Material

Pipe

Diameter(mm)

Pipe

Thickness(mm)

Capacity

(m/min)

S-ZG40

ss,cs,etc

6-31.8

0.2-1.0

1-20m/min

ZG40

ss,cs,etc

8-50.8

0.2-1.5

1-15m/min

B-ZG40

ss,cs,etc

8-63.5

0.3-2.0

1-10m/min

ZG50

ss,cs,etc

19.05-76.2

0.4-2.5

1-7m/min

ZG60

ss,cs,etc

38.1-114

0.5-3.0

1-5m/min

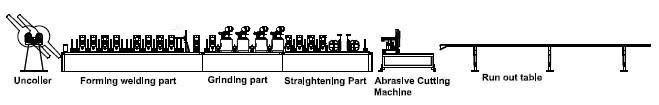

ZG80 ss,cs,etc 76.2-168 1.0-4.0 1-3m/min ZG100 ss,cs,etc 159-325 1.0-6.0 1-3m/min NOTE we can customize according to your requirement Pipe Machine’s Line-Up Arrangement (Stainless Steel Pipe)

-

un-coiler

-

Strip guide + Strip leveler

-

Forming Section ( Decorative: break down 3~4 + by-pass 3 + Fin pass 3~4 )

- Welding Section (Squeezing Roll set 3) + anti-twister (Welder: Tig/Plasma+Tig/Tig+Plasma+Tig, according to required

working thickness & speed)

- Seam polisher 3~4 units

- 1st sizing 2 (for decorative only one section 3~4 units required)

- Turk-Head (1 unit for round, 2~3 units for square)

- Flying Cutter

- Pipes collector

Pipe Machine Part Detail:

Part 1: Decoiler-Double sides(pipe making machine): manual operation with adjustable brake, can bear 1.5T per side.

Part 2: Logo stamping device(pipe making machine),can stamp company logo.

Part 3 : Forming Section(pipe making machine):

Needle Bearings in operation side Horizontal Stand, easier to change the Moulds and in high precision.

Vertical linkage adjuster,both sides of the shaft can be controlled to rise and fall at the same time, which is convenient for adjusting

the mold.

Part 4: Welding Section(pipe making machine):

we are using the Ultrasonic welding machine, it is can be running stable and make the welding line looks good.

Part 5: Totally enclosed automatic grinding head(stainless steel pipe making machine)

In automatically pressing down polishing system by electric motor, esay adjustment, saving time and labor.

And totally enclosed box with grinding head can make grinding section and workshop cleaner.

Part 6: Sizing & Straightening Section(pipe making machine):

this section can make the steel pipes more roundness.

Part 7: Turkey Head(pipe making machine)

Turkey Head can make the round pipe to the square pipe, round pipe to the rectangle pipe.

Part 8: Cutting Machine(pipe making machine)

Metal saw cutter, the pipe after the metal saw cutter, end of the pipe without the burr.

Part 9: Unloading Part(pipe making machine)

Run out of table, the steel pipe is collected here after cutting.

SS Pipes For Decorative Steel Pipe/Tube Making Machine Applicable for...

Pipe/tube making machine can produce round pipe, square pipe , rectangle pipe in same machine.

Our pipe/tube making machine also can customize, we can customize according to your need.

SS Pipe Making Machine For ASTM 554 Pipes & Tubes Application:

household commodities : shoe racks, clothes racks, retractable poles,article racks,etc.public facilities: guardrails, bus racks,flagpole,etc.furniture: tables, chair legs, storage rack,etc. Key words:

Key words:- Decorative Steel Pipe/Tube Making Machine

- tube making machine

- pipe making machine

- steel pipe making machine

- steel tube making machine

- stainless steel pipe making machine

- stainless steel tube making machine

Related Products

Guestbook

Write A Message To Us