SS Tube Mill Line for Heat Exchanger Pipes Manufacturer

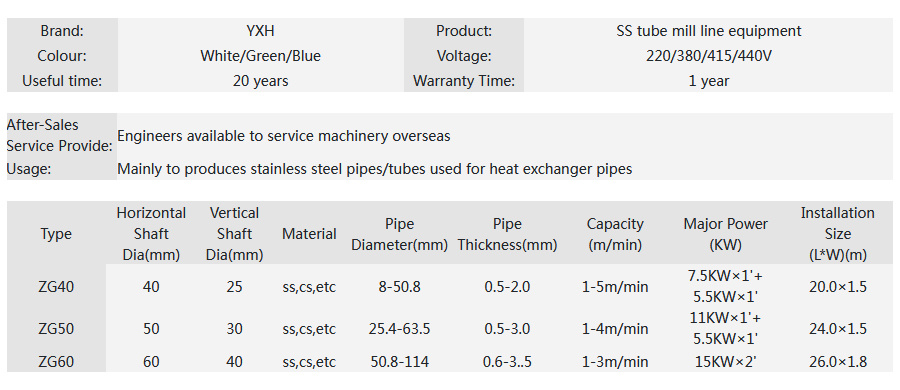

SS Tube Mill Line for Heat Exchanger Pipes Manufacturer mainly produces stainless steel pipes with diameter 12.7mm to 50.8mm, thickness 0.3mm to 2.5mm.

Category:

Phone/Whatsapp:

+86 18818745372

- Description

-

- Commodity name: SS Tube Mill Line for Heat Exchanger Pipes Manufacturer

- Commodity ID: 1070429436773027840

SS Tube Mill Line for Heat Exchanger Pipes Manufacturer mainly produces stainless steel pipes with diameter 12.7mm to 50.8mm, thickness 0.3mm to 2.5mm.

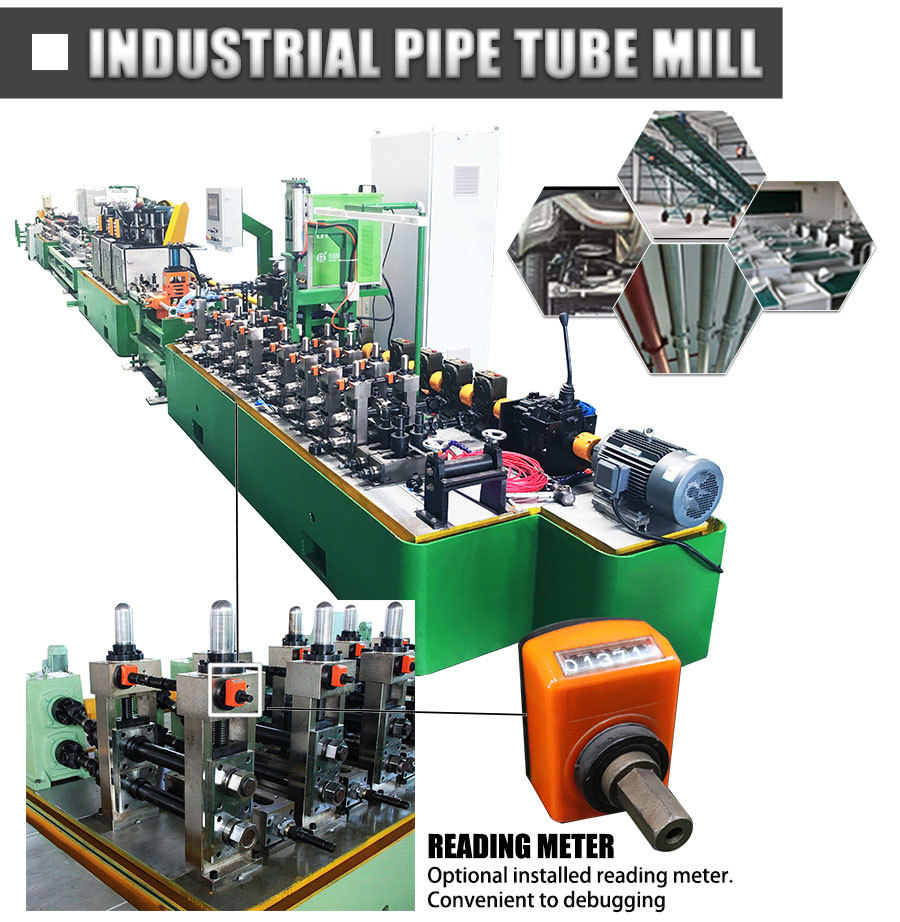

SS Tube Mill Line for Heat Exchanger Pipes Manufacturer1.The tube mill machine is welded by Q235 steel plate, world's top fivehundred BAOSTEEL material,machine vibration aging treatment。2.AI the key parts are processing by CNC machine centre to ensure the precision of equipment。3.Adopt Dong Feng auto transmission,enhanced turbine gearboxes ,ensure stability of transmission system4. Machine can be customized by customer' s requirements

SS Tube Mill Line for Heat Exchanger Pipes Manufacturer1.The tube mill machine is welded by Q235 steel plate, world's top fivehundred BAOSTEEL material,machine vibration aging treatment。2.AI the key parts are processing by CNC machine centre to ensure the precision of equipment。3.Adopt Dong Feng auto transmission,enhanced turbine gearboxes ,ensure stability of transmission system4. Machine can be customized by customer' s requirements SS Tube Mill Line's Line-Up Arrangement (Stainless Steel):

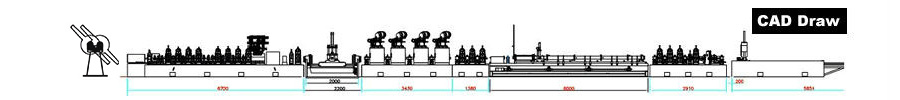

SS Tube Mill Line's Line-Up Arrangement (Stainless Steel):

- un-coiler

- strip jointer(optional)

- horizontal accumulater (optional)

- strip guide + strip leveler

- forming section (industrial : break down 4 + by - pass 3 +fin pass 4)

- welding section (squeezing roll set 3) + antitwister ( welder : Tig/Plasma + Tig/Tig +Plasma + Tig, according to required working thickness & speed)

- ECT (optiontal)

- seam polisher 3~4 units

- 1st sizing 2 (for decorative only one section 3~4 units required)

- bright annealing + anti-twister (optional)

- 2nd sizing(3~4)

- turk-head (1 unit for round, 2~3 units for square)

- ECT (eddy current tester)

- OD check (optional)

- flying cutter

- pipes collector

- inside bead rolling (min. OD 16mm, max speed 6 m/min)

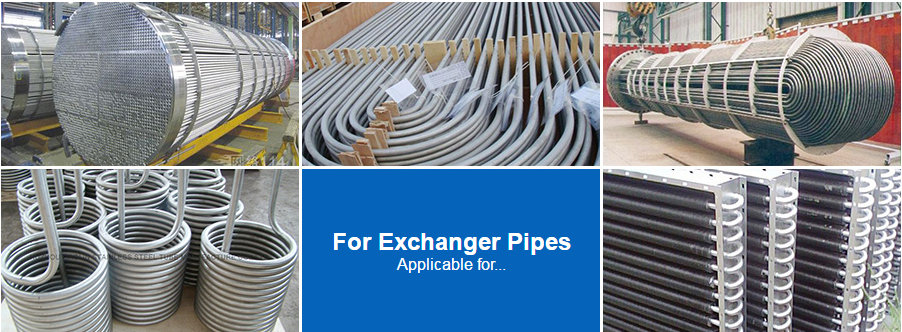

Application for SS Pipes - SS Tube Mill Line for Heat Exchanger Pipes Manufacturer

Key words : tube mill line pipe mill line pipe mill equipment tube mill equipment

Key words:- ss tube mill line

- ss tube mill

- tube mill

- tube mill line

Related Products

Guestbook

Write A Message To Us