Small Size SS Tube Making Machine

CSZG40 stainless steel tube making machine, covering range from 4mm to 25.4mm, and thickness is 0.18mm to 2.0mm. Stainless Steel Tube Making Machine with successive arrangement, easy to produce better quality small pipe (below 12.7mm) ,welding quality more stable,pipe more straight.

Phone/Whatsapp:

+86 18818745372

- Description

-

- Commodity name: Small Size SS Tube Making Machine

CSZG40 stainless steel tube making machine, covering range from 4mm to 25.4mm, and thickness is 0.18mm to 2.0mm. Stainless Steel Tube Making Machine with successive arrangement, easy to produce better quality small pipe (below 12.7mm) ,welding quality more stable,pipe more straight.

CSZG40 SS tube making machine is design to make small sizes steel tube, covering range from 4mm to 25.4mm, and thickness is 0.18mm to 2.0mm. This tube making machine is customized machine, with successive arrangement, easy to produce better quality small pipe (below 12.7mm) ,welding quality more stable,pipe more straight.

CSZG40 SS tube making machine is design to make small sizes steel tube, covering range from 4mm to 25.4mm, and thickness is 0.18mm to 2.0mm. This tube making machine is customized machine, with successive arrangement, easy to produce better quality small pipe (below 12.7mm) ,welding quality more stable,pipe more straight.Production Parameter

ModelMaterialDiameterThicknessCSZG40stainless steel ,carbon steel4mm - 25.4mm0.18mm - 2.0mmMachine Show

1. Froming section with successive arrangement: easy to produce better quality small tube (below 12.7 mm)2. Welding section with welding tracking system: It can automatically identify the position and shape of welding seams and realize automatic planning and control of welding trajectories.And with roundness mold for welding: it can accurately position the welding position and ensure the correct position of the welding joint.

1. Froming section with successive arrangement: easy to produce better quality small tube (below 12.7 mm)2. Welding section with welding tracking system: It can automatically identify the position and shape of welding seams and realize automatic planning and control of welding trajectories.And with roundness mold for welding: it can accurately position the welding position and ensure the correct position of the welding joint. 3. Bead Rolling Machine is used for on-line treatment of welded joints of stainless steel tube, rolling on the inner and outer welded joints repeatly to keep the joints smooth and make the welded pipe seamless.

3. Bead Rolling Machine is used for on-line treatment of welded joints of stainless steel tube, rolling on the inner and outer welded joints repeatly to keep the joints smooth and make the welded pipe seamless. 4. Grinding section with fully automatic grinding heads in closed design, in automatically pressing down polishing system by electric motor, easy adjustment, saving time and labor.5. Sizing section with straightening device6. Eddy current test system: If weld quality defects occur, it will be marked and the system will give an alarm.7. Metal saw cutter, the pipe cut by metal saw cutter ,end of the pipe without the burr.8. Tube recoiler: for coiling the final steel tubes.

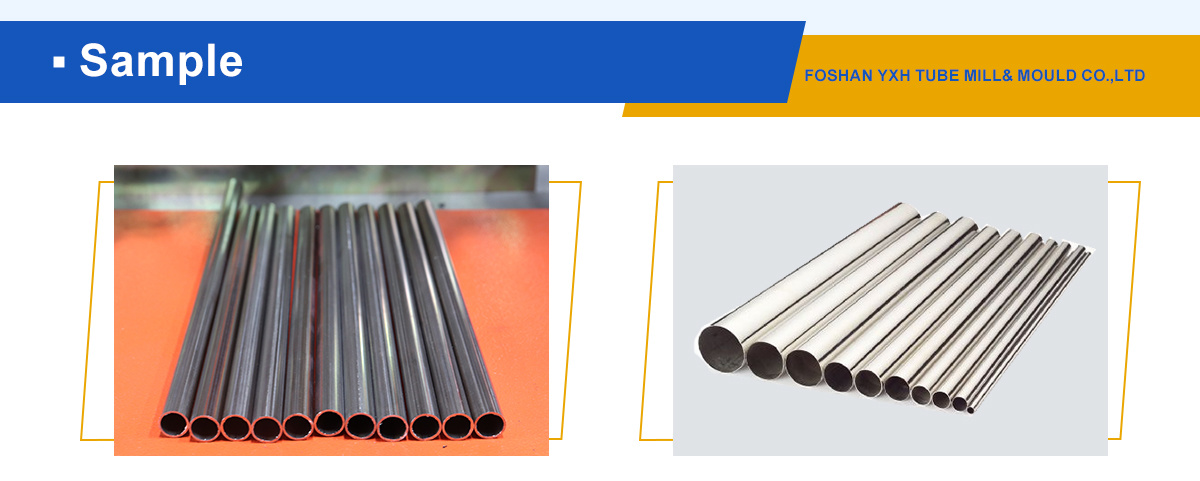

4. Grinding section with fully automatic grinding heads in closed design, in automatically pressing down polishing system by electric motor, easy adjustment, saving time and labor.5. Sizing section with straightening device6. Eddy current test system: If weld quality defects occur, it will be marked and the system will give an alarm.7. Metal saw cutter, the pipe cut by metal saw cutter ,end of the pipe without the burr.8. Tube recoiler: for coiling the final steel tubes.Finished Steel Tube

Application

Key words:

Key words:- tube making machine

- ss tube making machine

- small size tube making machine

Related Products

Guestbook

Write A Message To Us